C.R. s.r.l. -

BACK-

Back-

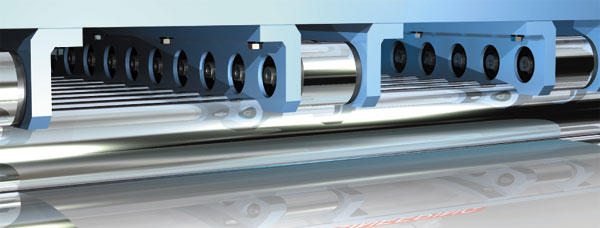

Full complement of cylindrical rollers & with roller cages in mould steel or bronze.

The full complement execution allows the bearing to reach a high load capacity both dynamic and static.

The wide working surface, along with the rolling system, made of two or more cages, allow the plant to reach very high flattening performance and high speed.

The distance rings, which are obtained entirely on the outer ring and the pivot, and the circle clearance, which is calculated at the minimum, allow a good support of axial loads.

The execution with roller cages represent the most advantage series of back-

The series of back-