Technical Drawing

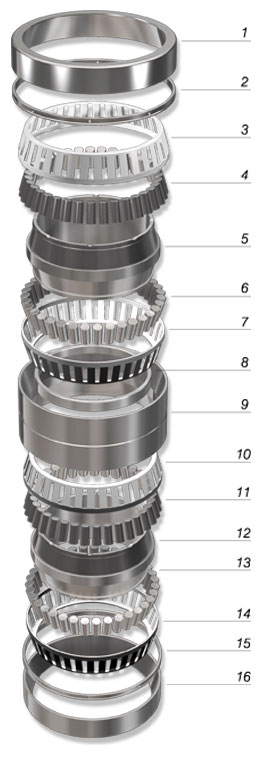

Exploded View

Home | Products | Steel Industry | Four-

Four-row tapered roller bearings

Cones and cups of four-

1 -

2 -

In both cases, hardness reaches the degree of 60-

The distance rings are manufactured in the same type of steel, whereas the cages

are manufactured in press-

All the bearings are provided with holes and lubrication grooves on the outer part.

Four-

Four-

The internal clearances are settled according to the application and in any case they are always marked with suffixes and numbers written on the drawings.

C.R. tapered roller bearings of this series undergo stabilization treatment, which allows them to be used up to 300° C without any dimensional modification.

Technical Characteristics

C.R. four-

1. Cone

2. Distance ring

3. Cage

4. Tapered rollers

5. Double cup

6. Tapered rollers

7. Cage

8. Distance ring

9. Double cone

10. Cage

11. Tapered rollers

12. Double cup

13. Tapered rollers

14. Cage

15. Distance ring

16. Cone

Esecution ETO

The bearings of this execution have two couples of rows with “X” shape. They have two double cones, one double cup and two single cups or four single cups.

Esecution ETOE

Like ETO execution, but with larger inner rings. Their extensions are grinded and act as ball raceways for the seals.

Esecution ETOT

Like ETO execution, but with the tapered hole, taper 1:12.

Esecution ETI

The bearings of this execution have two couples of “O” rows. They are made of one double cone and of two single cones or two double cups or four single cups.

These bearings usually have press-

They are also used on the vertical cylinders of all-

Esecution ETIT

Like ETI execution, but with taper hole, taper 1:12 or 1:30.

C.R. s.r.l. -