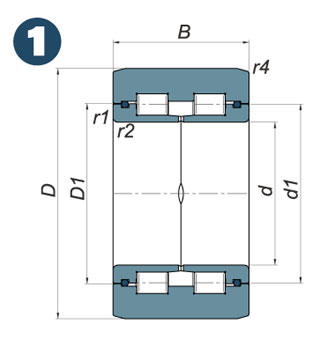

Technical Drawing

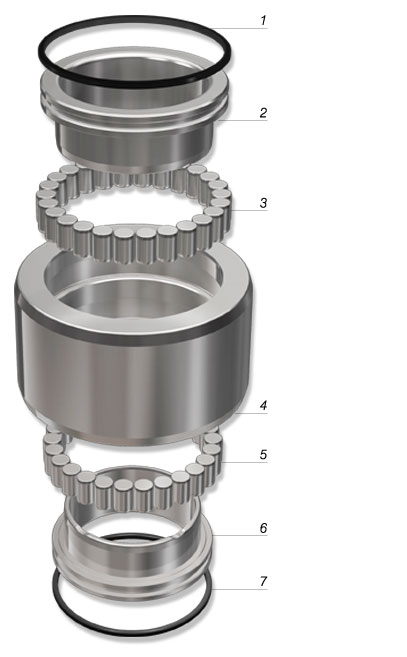

Exploded View

Home | Products | Steel Industry | Pressure rolls

Pressure-rolls

In order to increase the resistance to wear – due to high load and contamination of outer agents – pressure rolls usually undergo bainitic temper treatment with the following suffixes: TB1 means bainitic temper of both rings, TB2 means bainitic temper only of the outer ring.

Pressure rolls usually work at high temperatures, therefore they undergo stabilization treatment up to 250° C, named S2.

The sealing system foresees the presence of Viton O-

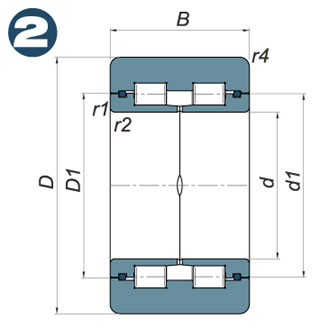

The outer ring shows three entire borders, one section and one outer surface which is highly resistant to wear.

The inner ring is made of two parts, each one has an entire border expressly developed in order to bear high axial thrusts, in addition to radial loads.

Pressure rolls do not need maintenance.

C.R. pressure rolls have the following technical characteristics:

The outer ring and the inner ring are manufactured in core-

This type of steel guarantees an excellent distribution of core-

The degree of hardness is 60-

Technical Characteristics

C.R. pressure rolls are mainly used in the continuous furnaces of sintering plants. They are massive bearings ready to be fixed.

They are used with heavy loads and where the rotation reverses continuously at low speed.

1. Viton o-

2. Inner ring

3. Cylindrical rollers

4. Outer ring

5. Cylindrical rollers

6. Inner ring

7. Viton o-

C: Dynamic load -

Cw: Dynamic load -

C.R. Ref.

900-

900-

900-

900-

900-

900-

900-

900-

900-

900-

900-

900-

900-

d1

mm

126

148

151

157

157

160

178

187

187

195

231

227

238

Cow

KN

390

600

450

325

455

560

850

750

1000

1830

1140

1340

1100

d

mm

93

100

105

110

120

128,665

140

140

140

160

160

160

180

D1

mm

127

149

153

158

158

162

180

188

188

197

233

228

240

D

mm

170

200

215

210

210

210

250

250

280

250

320

330

330

r1,2 min.

mm

2

4

3

2

4

4

3

3

3

3

4

4

4

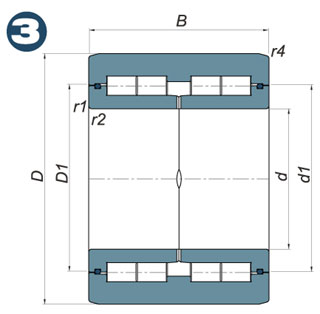

Esec.

type

1 TB2

1 TB2

2 TB1

1 TB2

1 TB2

1 TB2

1

1

1 TB1

3 TB1

1

1

1

C

KN

429

605

501

402

550

583

825

825

913

2120

1140

1140

968

Co

KN

655

1000

695

610

915

1120

1400

1400

1460

4400

2040

2040

1930

Cw

KN

286

413

358

255

330

352

561

512

671

1100

737

825

644

r3,4 min.

mm

10x15°

10X15°

10X15°

10X15°

10X15°

10X15°

11.5X17°

13.5X17°

13.5X15°

13.5X17°

13X17°

6.5X15°

6.5X15°

Bearing

Roller

Notes:

TB1= bainitic temper of inner and outer ring

TB2= bainitic temper of outer ring

C.R. s.r.l. -