Technical Drawing

Exploded View

Home | Products | Steel Industry | Cylindrical rollers for conveyor belts

Cylindrical rollers for conveyor belts

The inner ring is manufactured in case hardened UNI 100Cr6 steel with maximum hardness

degree 60-

Protection system has steel shields made with elastic layered steel rings.

Grease lubrication is made through a groove on the inner distance ring.

Considering the application of the cylindrical rollers, C.R. can supply execution with radial clearance C3/C4 and stabilizing heat treatment up to 250° C, on request.

The execution with cylindrical rollers is generally used with high radial loads, as this can absorb distortions and dilatations.

In comparison with the execution with tapered rollers, this execution is used near high heat sources.

The entire borders obtained in the outer ring allow the absorption of average axial thrusts.

Full-

The outer ring is usually manufactured in cementation UNI 16NiCr4 steel and reaches

hardness degree of 60-

Technical Characteristics

Full-

They are mainly used as support bearings in conveyor belts for coils.

C: Dynamic load

Co: Static load

C.R. Ref.

900-

900-

900-

900-

900-

900-

Max speed

RPM min-

1.100

900

700

550

400

300

D

mm

125

150

165

185

215

255

D1

mm

140

170

190

210

250

290

A

mm

40

50

55

60

65

70

B1

mm

60

70

75

80

85

90

C

KN

128

195

228

283

356

472

Co

KN

133

214

246

319

411

581

d

mm

50

60

70

80

100

120

B

mm

65

75

80

85

90

100

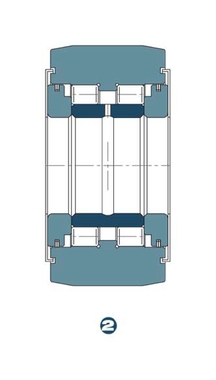

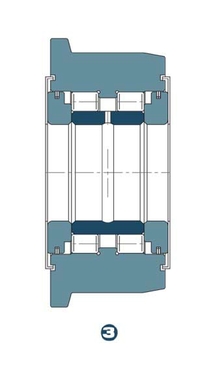

1. Seal sheet

2. Fey seal ring

3. Support thrust ring

4. Inner ring

5. Cylindrical rollers

6. Outer ring

7. Cylindrical rollers

8. Support thrust ring

9. Fey seal ring

10. Seal sheet

C.R. s.r.l. -