STRAIGHTERNERS OR STEEL LEVELERS

STRAIGHTENERS

OR STEEL LEVELERS

OR STEEL LEVELERS

IN THE HEART

OF STEEL LEVELER

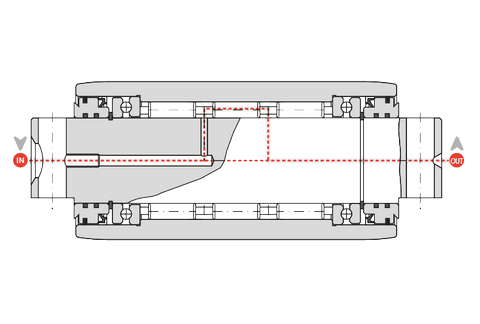

The heart of the leveler is represented by the structures,

the bridge – and in the heart of the machine – by the back-up rollers in the bank (cassette).

A steel leveler that can process harder and more resistant materials

is based on the leveling work rolls, which take advantage

of the high and consistent support given by the back-up bearings.

Old machinery used to adopt simple shells with internal oscillating bearings,

which - in the long terms - “climbed” on the work rolls,

and caused serious failures in the bank.

Suitable and reliable back-up rollers to rely on,

allow to obtain at least 40% of optimized leveling.

allow to obtain at least 40% of optimized leveling.

STEEL INDUSTRY SPECIAL SECTIONS

- STEEL MILL AND SENDZIMIR STEEL MILL

- STRAIGHTENERS OR STEEL LEVELERS

- TENSION LEVELER

- SINTERING PLANTS

- COIL CONVEYORS

- REVAMPING OF CASSETTES

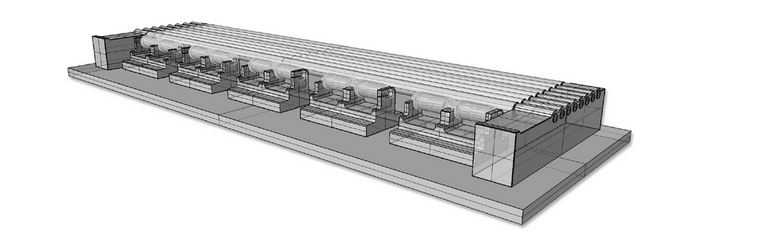

STEEL LEVELER CASSETTE

A PERFECT WORK

In order to get more effect on the leveling, we should take into consideration:

- alignment of the supporting structures for all back-up rollers;

- calibration of back-up rollers for the correct support on the leveling work rolls;

- correct calibration of the group of work rolls with all the supports;

- reliability and efficiency and quality of the material of the components.

CONTRAST ROLLS INTO THE STEEL LEVELER CASSETTE

Leveler and straightener machines can be provided with five typologies of back-up rolls.

C.R. manufactures all these typologies with the required technical features.

The back-up rolls for leveler and straighteners machines are very resistant to the applied loads and have a perfect combination between the tangent force and the grease tightness.

The metal flattening machines are manufactured with the possibility to quickly remove the cassette (work rolls and back-up rollers).

During maintenance phase, it is possible to insert the spare cassette so that the cost of the stop of the machine is dramatically reduced.

C.R. in accordance with service centers, can foresee the complete or partial revision of the back-up rollers, once verified the condition of them.

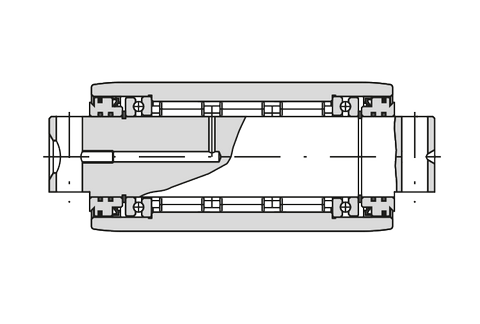

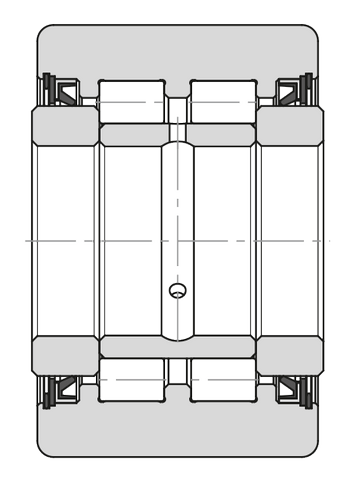

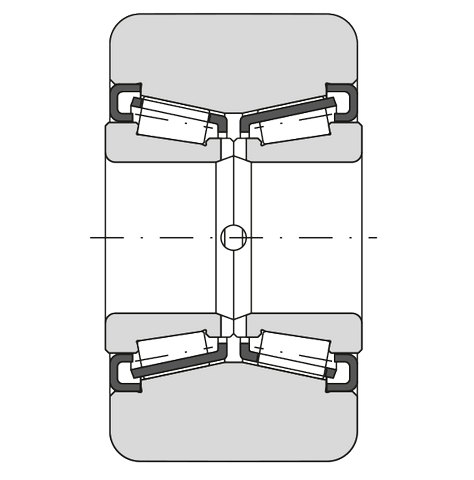

1 - BACK-UP ROLL WITH PIVOT2 - DOUBLE BACK-UP ROLL WITH PIVOT

1 - BACK-UP ROLL WITH PIVOT

Back-up rollers for metal flattening machines are made in two different executions:

- full complement of cylindrical rollers

- with roller cages in molded steel or bronze.

The full complement execution allows the bearing to reach a high load capacity both dynamic and static.

The wide working surface, along with the rolling system, made of two or more cages, allow the machine to reach very high leveling performance and high speed.

2 - DOUBLE BACK-UP ROLL WITH PIVOT

The distance rings, which are entirely obtained on the outer ring and shaft, and the radial clearance calculated at the minimum, allow a good support of the axial load.

The execution with roller cages represents the best project in the series of back-up rollers, usually manufactured with two lateral thrust bearings in the inner body, either with balls or rollers, which guarantee a very strong support of axial loads.

The execution with roller cages represents the best project in the series of back-up rollers, usually manufactured with two lateral thrust bearings in the inner body, either with balls or rollers, which guarantee a very strong support of axial loads.

LUBRICATION SYSTEM

LUBRICATION SYSTEM

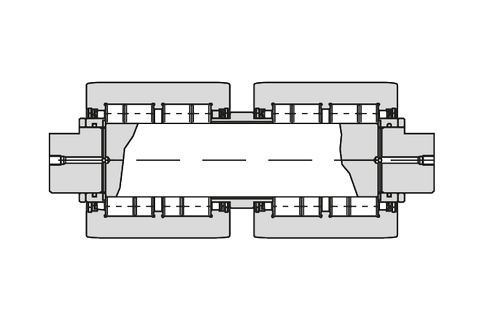

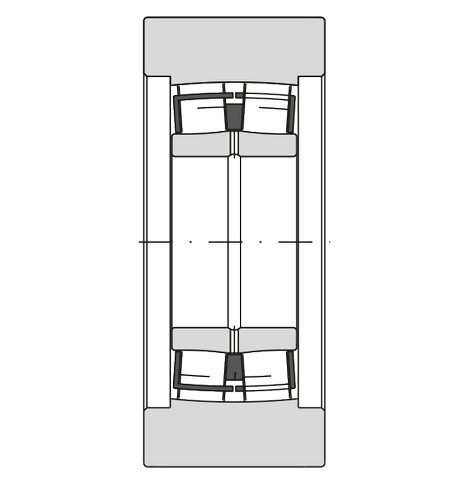

3 - SINGLE CYLINDRICAL ROLLER BACK-UP ROLL

The series of back-up rollers without pivot is manufactured with two or more full-complement-cylindrical-roller rows: they are separated by spacers obtained entirely on the outer ring.

These bearings are particularly used on machines that work continuously and in extremely tough conditions, because of their high dynamic and static load capacity.

The spacers between the rolling raceways guarantee the bearing of axial thrust.

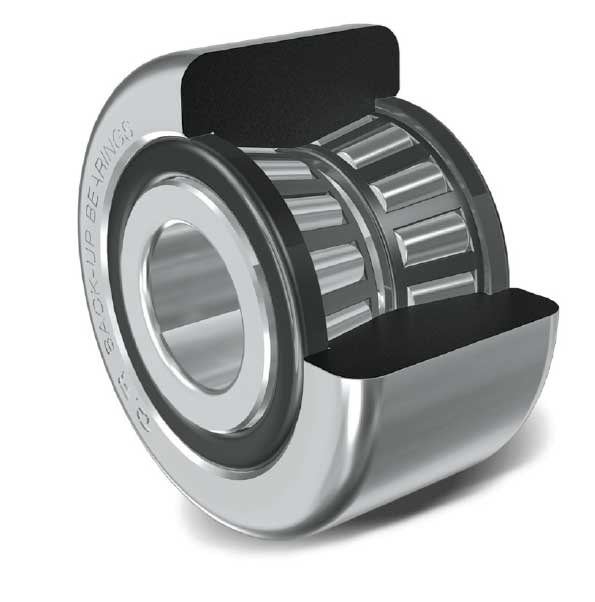

4 - SINGLE TAPERED ROLLER BACK-UP ROLL

Tapered roller back-up bearings in inch dimensions are mounted on sheet metal leveling machines operating under very heavy working conditions.

Their design is suitable to bear big axial loads together with big radial loads.

They are supplied for complete units ready for the assembling and produced in normal precision class. On request, the outer diameter can be manufactured with cambered or cylindrical shape.

Considering the working conditions, the sealing system is designed with rubber seals or with steel rings.

C.R. tapered roller back-up bearings are designed to allow a fast maintenance procedure both of the back-up and the whole cassette.

5 - SINGLE SPHERICAL ROLLER BACK-UP ROLL

The spherical roller bearings (execution in mm or inches) are used on metal flattening machines in rare cases.

This type of bearing can adapt, during the working phase, thanks to its oscillations, to the possible coupling irregularities between work roll and back-up bearing.

The carachteristic of being orientable allows the bearings to bear high loads, both axial and radial.

After the customer’s request, C.R. evaluates the possibility of manufacturing the pieces, by considering the quantity and the dimensions.